In the fast-paced world of automotive repair, efficiency is crucial for mechanics aiming to deliver top-notch service while minimizing downtime. A well-organized and fully equipped Car Tool Box serves as the foundation for a mechanic's daily operations. According to the Bureau of Labor Statistics, the employment of automotive service technicians is projected to grow by 4% from 2019 to 2029, underscoring the importance of arming these professionals with the right tools to meet increasing demands. A comprehensive Car Tool Box not only enhances productivity but also reduces the risk of errors, enabling mechanics to tackle repairs swiftly and confidently.

Moreover, a recent report by the National Institute for Automotive Service Excellence highlights that mechanics who utilize an organized tool system encounter 25% fewer delays and achieve a higher first-time fix rate. This emphasizes that investing in essential tools and ensuring they are easily accessible within a Car Tool Box can significantly impact a mechanic's efficiency and overall job satisfaction. As we explore the top essentials every mechanic should include in their Car Tool Box, we will unveil how these tools can transform a mechanic's workflow and contribute to a more streamlined repair process.

Every mechanic's toolbox should include a set of essential hand tools that enhance productivity and ensure effective repairs. A reliable set of wrenches is fundamental; both metric and standard sizes should be readily available to cope with various vehicles. Socket sets are equally critical, providing versatility for jobs ranging from simple maintenance to complex overhauls. A good selection of screwdrivers—flat, Phillips, and specialty types—will cater to a wide range of fasteners, enabling mechanics to tackle diverse tasks with ease.

Additionally, pliers in multiple variations, such as needle-nose and slip-joint, are indispensable for gripping, twisting, and cutting. A torque wrench is vital for achieving the correct tightness on bolts and nuts, which is crucial for maintaining vehicle integrity. Furthermore, adding adjustable wrenches enhances flexibility, allowing mechanics to work with different sizes without needing a comprehensive set. All these tools, when organized effectively in a toolbox, empower mechanics to operate with ultimate efficiency, facilitating swift problem-solving and high-quality workmanship on every job.

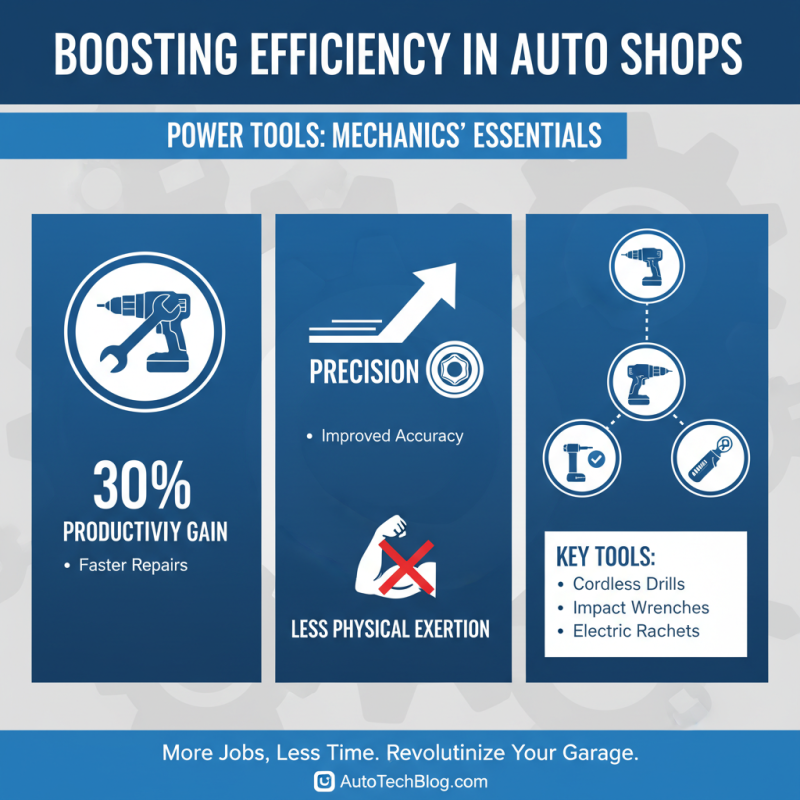

When it comes to enhancing efficiency in automotive workspaces, power tools are indispensable for mechanics. According to recent industry reports, mechanics can boost productivity by 30% through the strategic use of high-quality power tools. These essential tools not only reduce labor time but also improve the precision of repairs. Cordless drills, impact wrenches, and electric ratchets are just a few examples that have revolutionized the way tasks are approached in the garage. The quick adjustments and less physical exertion required by these tools allow mechanics to tackle more jobs in a single day.

Tips for maximizing the use of power tools include regular maintenance to ensure peak performance and safety. Keeping tools well-charged and organized can prevent downtime and help mechanics maintain workflow efficiency. Additionally, investing in tools with ergonomic designs can minimize strain during prolonged use, promoting a healthier work environment. Generally, mechanics with high-functioning tools not only complete tasks more quickly but also deliver higher quality work, which can directly impact customer satisfaction and repeat business.

Furthermore, training on the latest power tools can significantly enhance operational efficiency. Understanding the full capabilities of each tool allows mechanics to use the right tool for the right job, subsequently reducing time spent on tasks. As 58% of mechanics report increased job satisfaction when utilizing advanced tools, embracing technology is crucial not only for efficiency but also for employee morale. In an ever-evolving industry, staying updated on the latest power tools will empower mechanics to excel in their craft.

When it comes to automotive repair, having the right specialized tools at your disposal can make all the difference in efficiently resolving common issues. Every mechanic should prioritize having a comprehensive set of tools that cater specifically to the tasks at hand. For instance, an OBD-II scanner is essential for diagnosing engine trouble codes, saving time and enabling quicker fixes. Additionally, a torque wrench is critical for ensuring that bolts are tightened to the manufacturer’s specifications, which can prevent potentially costly mistakes in repairs.

Tips: Always keep an eye on your tool collection and replace worn-out tools promptly. Having a dedicated toolbox that is organized can not only enhance efficiency but also reduce the chances of losing tools or misplacing them during a job. Regularly checking for common automotive tools, such as specialized screwdrivers and wrenches, can save you time and effort when tackling different kinds of repairs.

Moreover, investing in a good set of impact sockets for removing stubborn bolts can significantly improve your workflow. These sockets are designed to handle the high torque required in many automotive applications and can also reduce the risk of stripping bolts. By keeping these specialized tools in your arsenal, you empower yourself to tackle a broader array of repairs with confidence and speed.

Maintaining an efficient and accessible toolbox is crucial for any mechanic aiming to boost productivity and streamline workflows. According to a survey conducted by the National Institute for Automotive Service Excellence (ASE), approximately 70% of auto mechanics report that organizational issues significantly impede their ability to work efficiently. A well-structured toolbox not only saves time but also reduces the risk of losing essential tools, leading to fewer disruptions during repairs and diagnostics.

To achieve optimal organization, mechanics should employ a systematic approach that categorizes tools based on usage and function. For instance, grouping hand tools, power tools, and specialty tools can make it easier to find what you need quickly. Implementing clear labeling systems, along with designated spaces for frequently used items, can reduce downtime.

A study by the American Society of Mechanical Engineers (ASME) revealed that such organizational methods can cut tool retrieval time by up to 30%. Additionally, investing in tool organizers like trays, magnetic strips, or drawer dividers can enhance accessibility and ensure that tools remain in good condition, ultimately leading to improved workflow efficiency.

When it comes to mechanics, safety should always be the top priority. Having the right safety equipment not only protects the individual but also enhances overall efficiency in the workshop.

Essential safety gear includes well-fitted safety goggles that shield the eyes from flying debris and harmful chemical splashes. Additionally, industrial-grade gloves provide a reliable barrier against sharp objects and hazardous materials, ensuring that hands remain safe while effectively handling tools and components.

Equally important is the use of durable steel-toed boots, which offer critical protection against heavy tools and equipment that might accidentally fall. Mechanics should also invest in high-visibility vests, especially when working in environments with vehicular traffic, to increase awareness among coworkers and enhance overall safety.

Furthermore, ear protection is vital in reducing the risks associated with loud machinery and tools, helping to prevent long-term hearing damage. By prioritizing these safety essentials, mechanics can create a secure working environment, allowing them to focus on their tasks with heightened confidence and efficiency.