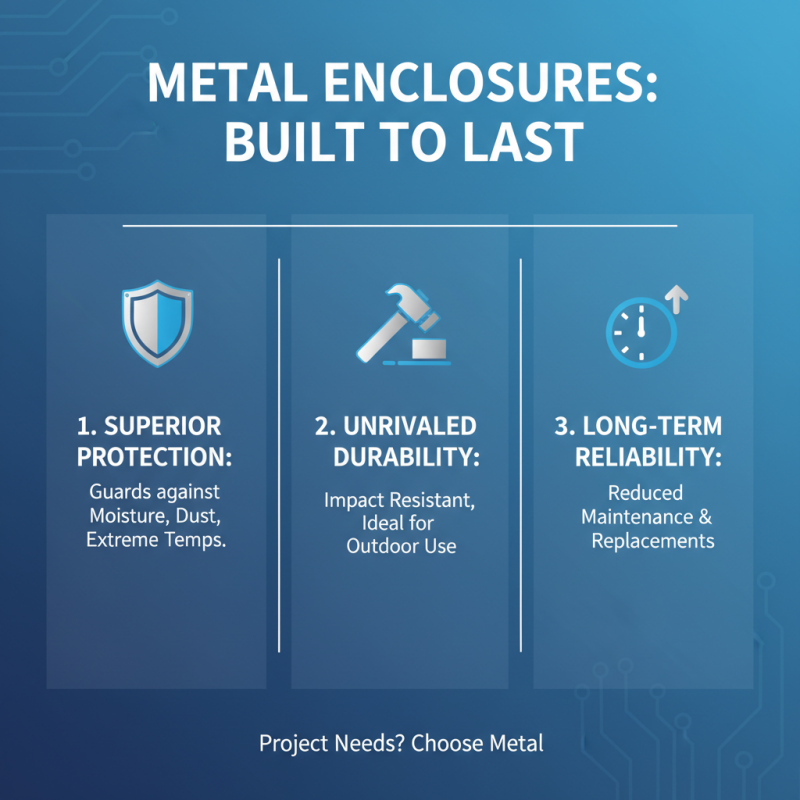

When embarking on a new project, one of the critical decisions to make is the selection of the right materials and enclosures. A Metal Enclosure Box stands out as a reliable and versatile choice for various applications, offering unique benefits that enhance both functionality and durability. The robust nature of metal enclosures provides superior protection against environmental factors, including moisture, dust, and impact, ensuring that sensitive components inside are shielded from potential damage.

Apart from their protective qualities, Metal Enclosure Boxes contribute to effective heat dissipation and electromagnetic shielding, making them ideal for electronic projects where performance and safety are paramount. Additionally, their structural integrity allows for a longer lifespan compared to plastic alternatives, reducing the need for frequent replacements and offering a sustainable option for project developers. This introduction sets the stage for exploring the multifaceted advantages of choosing a Metal Enclosure Box, positioning it as an essential element in achieving project goals with confidence and precision.

When selecting an enclosure for your project, a metal enclosure box stands out due to its durability and reliability. Unlike plastic alternatives, metal enclosures offer superior protection against environmental factors and physical damage. According to a report by the Communication and Electronics Research Institute, around 70% of equipment failures are due to environmental influences; metal enclosures significantly mitigate this risk, enhancing the longevity of electronic components housed within. Furthermore, metal enclosures provide excellent electromagnetic interference (EMI) shielding, which is crucial for maintaining signal integrity in sensitive applications.

Another advantage of using metal enclosure boxes is their customizable nature. They can be easily modified to suit various project requirements, whether it's for industrial automation or consumer electronics. The versatility of metal allows for effective heat dissipation, which is essential in preventing overheating of electronic devices. A recent study from the Institute of Electrical and Electronics Engineers highlighted that projects utilizing metal enclosures experienced a 30% reduction in failure rates compared to those using plastic options.

Tips: When opting for a metal enclosure, consider the intended environment of your project. Evaluate parameters such as temperature fluctuations, humidity levels, and potential exposure to chemicals. Additionally, ensure that the chosen enclosure has adequate ventilation if your equipment generates heat. Proper planning at this stage will contribute to the successful implementation and longevity of your project.

When considering project needs, the choice of enclosure is crucial. Metal enclosures stand out for their unparalleled durability and protection. Unlike plastic options, metal enclosures provide robust shielding against environmental factors such as moisture, dust, and extreme temperatures. This inherent strength makes them ideal for outdoor applications and settings where impact resistance is paramount. The longevity of metal materials means that projects can be built to last, reducing the need for frequent replacements and maintenance.

In addition to physical protection, metal enclosures offer excellent electromagnetic shielding. This feature is particularly beneficial in industrial and electronic applications where interference can lead to performance issues. By incorporating a metal enclosure, projects can not only safeguard sensitive components but also enhance overall reliability. Furthermore, metal's sustainable nature adds an eco-friendly angle, as these enclosures can often be recycled, supporting more environmentally conscious project designs. Thus, the use of metal enclosures not only ensures protection but also provides a strategic advantage for various project requirements.

When selecting a metal enclosure for your project, several design considerations must be taken into account to ensure functionality and protection. Firstly, the environmental factors, such as temperature, humidity, and exposure to chemicals, play a crucial role in determining the type of metal and finish required. According to a report by MarketsandMarkets, the global metal enclosure market is projected to reach USD 3.1 billion by 2025, driven by increasing demand for robust, durable housing solutions in various industries, including electronics and telecommunications. Choosing materials like aluminum or stainless steel can provide excellent resistance to corrosion and harsh conditions, thereby extending the lifespan of your equipment.

Another critical aspect is the size and layout of the enclosure. It is vital to consider the dimensions necessary to accommodate all components without cramping, as well as ensuring adequate cooling for heat dissipation. The National Electrical Manufacturers Association (NEMA) categorizes enclosures based on their protection levels, ranging from indoor use to harsh outdoor environments. This classification can guide designers in selecting the appropriate enclosure that meets both safety standards and project specifications. Furthermore, ease of access for maintenance and installation should also be factored in, as a well-designed enclosure can significantly reduce downtime and operational costs in the long run.

| Feature | Benefit | Considerations |

|---|---|---|

| Durability | Resistant to physical damage and impact | Ensure adequate thickness based on application |

| Heat Dissipation | Better thermal management for electronics | Design ventilation holes if necessary |

| Security | Provides a secure environment for sensitive equipment | Consider locking mechanisms for added security |

| EMI Shielding | Protects against electromagnetic interference | Evaluate the need based on project requirements |

| Customization | Options for tailored sizes and features | Specify dimensions and features on the design phase |

| Corrosion Resistance | Longer lifespan in harsh environments | Select appropriate coating for specific environments |

When considering project requirements, the cost-effectiveness of metal enclosures often shines through when compared to alternative materials. According to a recent market analysis, metal enclosures typically provide a life cycle cost that is approximately 20-30% lower than that of plastic enclosures over a ten-year period. This is largely due to the durability and longevity of metal, reducing the need for replacements and maintenance that often accompany weaker materials. The robustness of metal enclosures can withstand harsh environmental conditions, making them a sustainable choice for both indoor and outdoor applications.

Moreover, the total cost of ownership (TCO) emphasizes the advantages of metal enclosures beyond initial purchasing costs. In 2022, studies indicated that companies utilizing metal enclosures reported a 15% decrease in operational costs related to equipment failures. This benefit stems from the enhanced protection provided by metal casings against external factors like temperature fluctuations and physical impacts. By minimizing the risk of equipment damage, businesses not only save on repair expenses but also enhance productivity by reducing downtime. Therefore, when evaluating project needs, metal enclosures can offer a superior return on investment by balancing upfront costs with long-term savings.

Metal enclosure boxes play a crucial role across a variety of industries, providing robust protection for electronic and electrical equipment. In the manufacturing sector, for instance, the global metal enclosure market is expected to reach approximately $3.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.3%. This growth is driven by the increasing demand for protective housing solutions for industrial automation systems and robotics, where durable enclosures safeguard sensitive components from harsh environments, dust, and moisture.

In the telecommunications field, metal enclosures are vital for housing networking equipment that must withstand outdoor conditions. According to a recent report, the telecom enclosure market is projected to grow significantly, with outdoor enclosures specifically seeing a surge in use due to their ability to protect critical infrastructure from extreme temperatures and vandalism. Additionally, in the renewable energy sector, metal enclosures are commonly used to protect solar inverters and battery storage systems, contributing to the industry's expansion and supporting the global shift toward sustainable energy solutions.

Through their versatility and effectiveness, metal enclosure boxes remain indispensable across various sectors, ensuring equipment reliability and longevity.