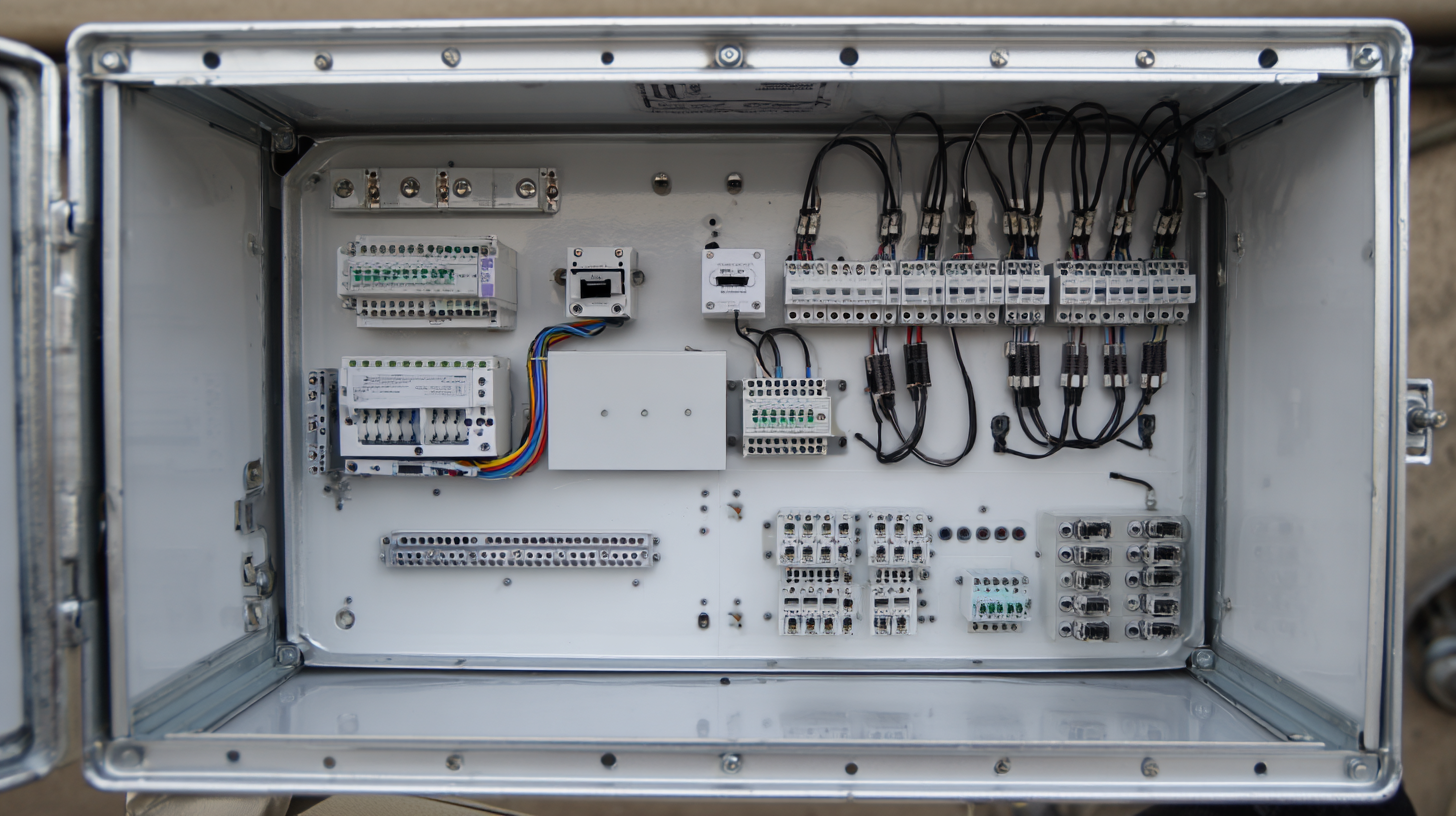

When it comes to protecting sensitive equipment and ensuring optimal performance in various industrial settings, choosing the right Metal Enclosure Box is essential. These robust structures are designed to safeguard electronic components, control systems, and other valuable assets from environmental hazards, tampering, and mechanical damage. However, with an array of options available in the market, selecting the best Metal Enclosure Box for your business needs can be a daunting task.

In this blog, we will explore practical industry application cases that highlight the significance of metal enclosures across diverse sectors, as well as provide a comprehensive guide on how to choose the perfect model that aligns with your specific requirements. Whether you're in manufacturing, telecommunications, or any field that relies on durable housing solutions, understanding the intricacies of Metal Enclosure Boxes will empower you to make an informed decision that enhances both safety and efficiency in your operations.

When selecting a metal enclosure box for your business, understanding export and import certifications is crucial. These certifications ensure that the enclosures meet international quality standards, which can affect regulations, safety, and performance. For companies looking to import metal enclosures, familiarity with the required certifications can prevent costly delays and compliance issues at customs. Each country may impose specific standards, and being informed about these can help businesses navigate the complex landscape of international trade smoothly.

When selecting a metal enclosure box for your business, understanding export and import certifications is crucial. These certifications ensure that the enclosures meet international quality standards, which can affect regulations, safety, and performance. For companies looking to import metal enclosures, familiarity with the required certifications can prevent costly delays and compliance issues at customs. Each country may impose specific standards, and being informed about these can help businesses navigate the complex landscape of international trade smoothly.

Moreover, certifications not only facilitate the legal aspects of importing and exporting but also build trust with customers. When a product has the appropriate certifications, it signals reliability and safety, which are paramount in many industries. It is essential to inquire about certifications such as ISO, CE, or UL when sourcing metal enclosure boxes. These marks indicate that the products have undergone rigorous testing, thus ensuring they can withstand various environmental conditions while protecting the sensitive electronics within. In summary, prioritizing export and import certifications is vital for ensuring business integrity and product reliability.

When selecting a metal enclosure box for your business, one of the primary factors to consider is certification compliance. Certification ensures that your enclosures meet industry standards for safety and performance, allowing you to avoid potential legal and operational challenges. Achieving recognition certification for electrical enclosures typically involves meeting specific criteria laid out by regulatory bodies. This is crucial, especially as new certifications emerge that target particular components within access hardware, expediting the timeline from design to market.

Furthermore, evaluating the materials and construction of the enclosure can greatly influence compliance outcomes. Metal enclosures should be made from robust materials that can withstand environmental factors while maintaining electrical integrity. Additionally, understanding the testing processes required for certification, including aspects such as durability and environmental resistance, must inform your decision. Taking these key factors into account not only enhances product reliability but also fosters trust with customers who rely on your commitment to quality standards in critical applications.

When selecting a metal enclosure box for your business, understanding the necessary certifications is crucial. Different markets impose distinct standards to ensure safety, durability, and compliance. For instance, electrical enclosures often require UL (Underwriters Laboratories) certification to verify that products meet stringent safety standards in the United States. Similarly, CE marking is essential for products entering the European market, indicating compliance with health, safety, and environmental protection standards.

Tips: Always verify the specific certifications needed for your industry to avoid costly fines or product recalls. It's also beneficial to consult with manufacturers about their compliance with relevant standards, as this can impact the quality and performance of the enclosure.

In addition to safety certifications, consider environmental certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). These indicate a commitment to reducing hazardous material usage, which is increasingly important for businesses seeking to improve sustainability and reduce their environmental footprint.

Tips: Research industry trends influencing certification requirements, as these can evolve over time. Staying informed helps ensure that your metal enclosures not only meet current standards but are also future-proof.

When selecting metal enclosure suppliers, verifying their certification status is crucial for ensuring that you receive quality and compliant products. Certifications such as ISO 9001, UL, or CE indicate that a supplier meets specific industry standards and quality requirements. To begin your verification, request documentation that demonstrates their certifications. This can typically be found on the supplier's website or can be provided upon request. Additionally, check for any recent audits or assessments that attest to their compliance with these standards.

It’s also wise to assess how current the supplier’s certifications are. Certification bodies often conduct regular evaluations, so staying informed about any lapses or updates can provide insights into the supplier's reliability. Furthermore, consider reaching out to the certifying organizations to confirm the validity of the supplier’s claims. This diligence not only protects your investment but also ensures that the metal enclosures you procure will meet the necessary safety and performance standards, ultimately aligning with your business's long-term goals.

| Criteria | Importance Level | Verification Method | Typical Certifications | Standard Compliance |

|---|---|---|---|---|

| Material Quality | High | Supplier Material Specifications | ISO 9001 | EN 60601 |

| Size and Dimensions | Medium | Dimensional Inspection Reports | UL Listed | NEMA Ratings |

| Ingress Protection (IP Rating) | High | IP Rating Certificates | IP54 / IP65 | IEC 60529 |

| Thermal Management | Medium | Thermal Performance Tests | RoHS Compliance | WEEE Directive |

| Weight and Portability | Low | Load Testing | CE Marking | ASTM Standards |

When selecting a metal enclosure box for your business needs, ensuring compliance with industry standards is paramount. It's essential to familiarize yourself with the standards relevant to your specific application, such as NEMA (National Electrical Manufacturers Association) ratings, which dictate the environmental protection and safety features of electrical enclosures. Adhering to these standards not only enhances product reliability but also assures customers of quality and safety.

Implementing best practices in metal enclosure manufacturing involves rigorous testing and quality control processes. Manufacturers should conduct thorough inspections to verify that the materials used meet specified standards, and that the welding and sealing techniques are robust. Documentation of compliance, including certification records and test results, is crucial for transparency and building trust with stakeholders. Furthermore, staying updated on industry trends and regulatory changes helps companies adapt and maintain compliance, ultimately supporting their operational integrity and market competitiveness.