In the realm of industrial organization and efficiency, the "Drawer Type Parts Box" has emerged as an indispensable tool. According to John Smith, an industry expert with over two decades of experience in inventory management systems, "The versatility and accessibility of a Drawer Type Parts Box make it a game changer for businesses looking to streamline their operations." This innovative storage solution is designed to facilitate easy access to a variety of small parts and components, which is crucial for maintaining productivity in manufacturing and assembly processes.

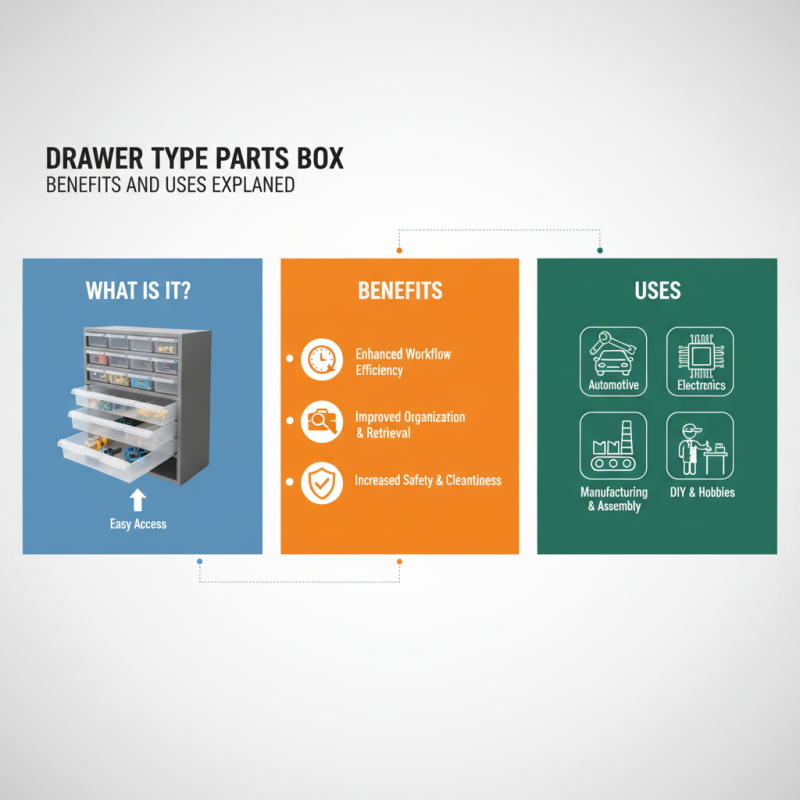

The benefits of utilizing a Drawer Type Parts Box extend beyond simple organization; they encompass enhanced workflow efficiency and improved safety. By categorizing tools and components in drawers, employees can not only find what they need quickly but also reduce clutter in the workspace. As the demands of modern industries evolve, so too does the need for optimized storage solutions. The Drawer Type Parts Box stands out as a practical option, catering to a diverse array of sectors, from automotive to electronics, ensuring that every component has its rightful place while fostering a more structured operational environment.

A drawer type parts box is specifically designed to provide an organized and efficient way to store and manage various components, tools, and parts. Its structural design typically features multiple compartments that can be accessed through pull-out drawers, allowing users to easily identify and retrieve items without clutter. This type of storage solution is especially useful in manufacturing, automotive repair, and even home workshops, where quick access to parts is imperative.

According to industry reports, efficient organization can lead to a productivity increase of up to 30%, making drawer type parts boxes a popular choice among professionals.

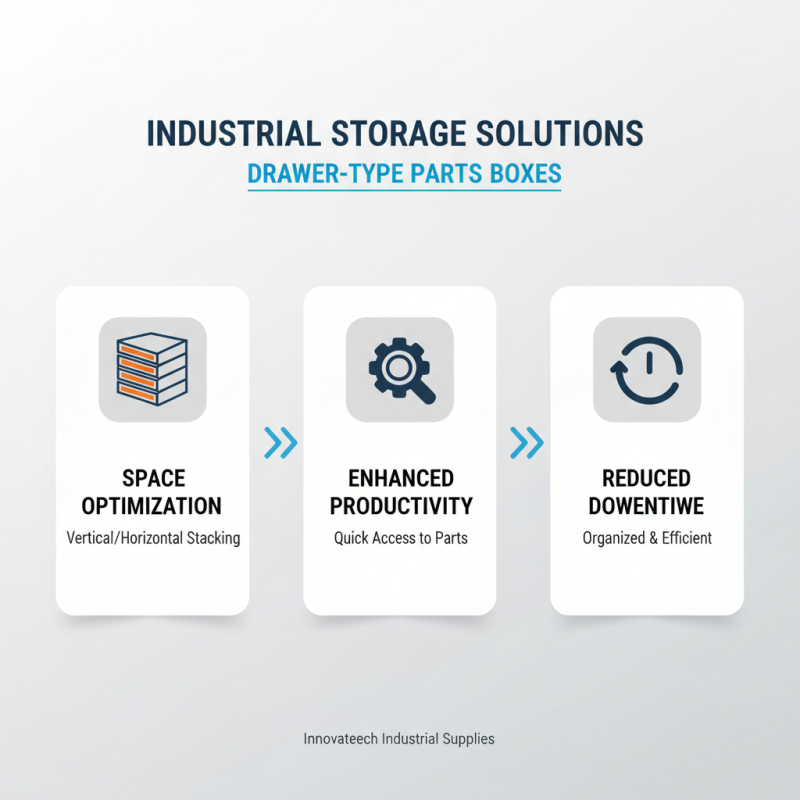

One significant advantage of drawer type parts boxes is their versatility. They can accommodate a wide range of items, from small screws and bolts to larger tools, and often come with customizable drawer inserts. This adaptability enables users to optimize their storage space according to their specific needs. Moreover, the compact design often allows for stacking, which further maximizes storage efficiency, particularly in environments with limited space.

Research from storage industry studies indicates that utilizing modular storage solutions can reduce retrieval times by 25%, which is crucial in fast-paced work settings.

Tips: When organizing your drawer type parts box, label each drawer clearly to save time when searching for parts. Additionally, consider using dividers within drawers to separate different categories of items, helping maintain order. Regularly reassessing the contents of your parts box can help you identify items that may need to be reordered or discarded, keeping your workspace clutter-free.

Drawer type parts boxes are essential organizational tools widely used in workshops, garages, and manufacturing settings. These boxes are designed with multiple drawers that allow for the efficient storage of small parts, tools, and components, helping to maintain a clean and organized workspace. The modular design of these boxes offers flexibility, enabling users to easily categorize and access their items when needed.

Key features: Durable construction materials such as steel or heavy-duty plastic ensure longevity and protect the contents from damage. Many boxes feature transparent drawers, making it easy to identify items at a glance. Additionally, these boxes often come with various drawer sizes, allowing for the storage of items ranging from screws and nuts to larger tools. Some models may even include locking mechanisms for added security, ensuring that valuable tools and parts are safe from theft or misplacement.

Tips: When organizing your drawer type parts box, categorize items by size or function to enhance efficiency. Use labels for each drawer to quickly locate needed components without rummaging through the box. Regularly declutter and remove unused items to maximize space and maintain an orderly system.

Drawer type parts boxes are essential tools in industrial settings, providing organized storage solutions for small parts and components. One of the primary benefits of using these boxes is their ability to maximize space utilization. With a design that allows for multiple drawers stacked vertically or horizontally, they efficiently use limited floor space while providing quick access to tools and materials. This organized approach not only enhances productivity but also minimizes the time workers spend searching for supplies, leading to smoother operations.

Tips for maintaining an efficient drawer type parts box include regularly labeling each drawer clearly. This practice aids in quick identification of contents, reducing frustration and downtime. Additionally, implementing a routine for checking inventory can help prevent supply shortages, ensuring that essential parts are always available when needed. Lastly, ensuring that all items stored are returned to their designated drawers after use promotes orderliness and encourages a culture of neatness in the workplace.

Utilizing drawer type parts boxes also contributes to safety in industrial environments. By keeping small parts organized and secure, these boxes reduce the risk of accidents caused by tripping over loose items or misplacing critical tools. Moreover, the clear visibility into each drawer helps workers identify needed parts at a glance, making the work environment less hectic and more efficient.

Drawer type parts boxes are versatile storage solutions commonly used across various industries due to their efficient organization capabilities. These boxes are designed with multiple drawers that allow users to categorize and store different types of parts, tools, and materials in one compact unit. In manufacturing plants, for instance, they help streamline operations by ensuring that each part is easily accessible, minimizing downtime during assembly or repair processes. Similarly, in automotive shops, these boxes are invaluable for organizing tools and components, enhancing workflow efficiency.

In addition to manufacturing and automotive applications, drawer type parts boxes are beneficial in electronics and woodworking industries. In electronics, they provide a systematic way to store small components, such as resistors and capacitors, preventing loss and facilitating quick access during projects. For woodworkers, these boxes can house various hardware, such as screws, nuts, and bolts, ensuring that everything is organized and in one place.

Tips: When selecting a drawer type parts box, consider the size and weight of the items you plan to store. Choose a box with sturdy construction and smooth drawer mechanisms to ensure durability and ease of use. Additionally, labeling the drawers can greatly enhance efficiency, making it easier to locate items when needed.

When comparing drawer type parts boxes to other storage solutions, several key differences stand out. Drawer type boxes offer organized compartments that make it easier to categorize and access various components. This design is particularly advantageous for those who frequently need to reach for specific items, as the drawers provide a clear view of their contents without the need to rummage through piles of materials. In contrast, traditional bins or open shelving may result in disorganization, where items can easily become mixed up, making retrieval time-consuming.

Another significant advantage of drawer type storage is its ability to maximize space efficiency. These units often have a vertical design, allowing them to fit into tighter areas while still providing ample storage capacity. Unlike bulkier shelving units or cabinets, drawer systems can be expanded or customized according to the user’s needs, providing flexibility that is often lacking with other types of storage. Additionally, the enclosed nature of drawer type boxes helps protect small parts from dust and debris, ensuring that components remain clean and ready for use.

| Feature | Drawer Type Parts Box | Bin Type Storage | Shelf Type Storage |

|---|---|---|---|

| Organization | High, allows easy access to tools and parts | Moderate, can become cluttered | Low, items may be hard to reach |

| Space Efficiency | Very efficient, maximizes vertical space | Moderate, can take up more horizontal space | Low, often requires larger footprint |

| Accessibility | Excellent, drawers slide out for easy access | Good, bins can be pulled out but may involve digging | Variable, items on higher shelves are hard to reach |

| Durability | High, often made from robust materials | Moderate, can crack or fade over time | High, sturdy shelves last long but weight needs consideration |

| Cost | Medium to high, depending on design | Low to medium, generally affordable | Low, but often requires additional organizing systems |